Top Electrical Insulation Grades for Safety in 2026: A Complete Guide

Electrical safety is more critical than ever in 2026, especially as homes, industries, and gadgets become more reliant on electricity. One of the key factors in maintaining safety and efficiency is choosing the right electrical insulation grade. This article will guide you through the top electrical insulation grades, their applications, and how they ensure safety, helping you make informed decisions.

What Are Electrical Insulation Grades?

Electrical insulation grades define a material’s ability to withstand heat and electrical stress without degrading. Choosing the correct grade can prevent accidents, extend equipment life, and improve overall efficiency.

Key factors to consider:

-

Thermal resistance – Can the insulation handle high temperatures?

-

Dielectric strength – Resistance to electrical breakdown.

-

Chemical stability – Ability to resist environmental factors like moisture, oil, or chemicals.

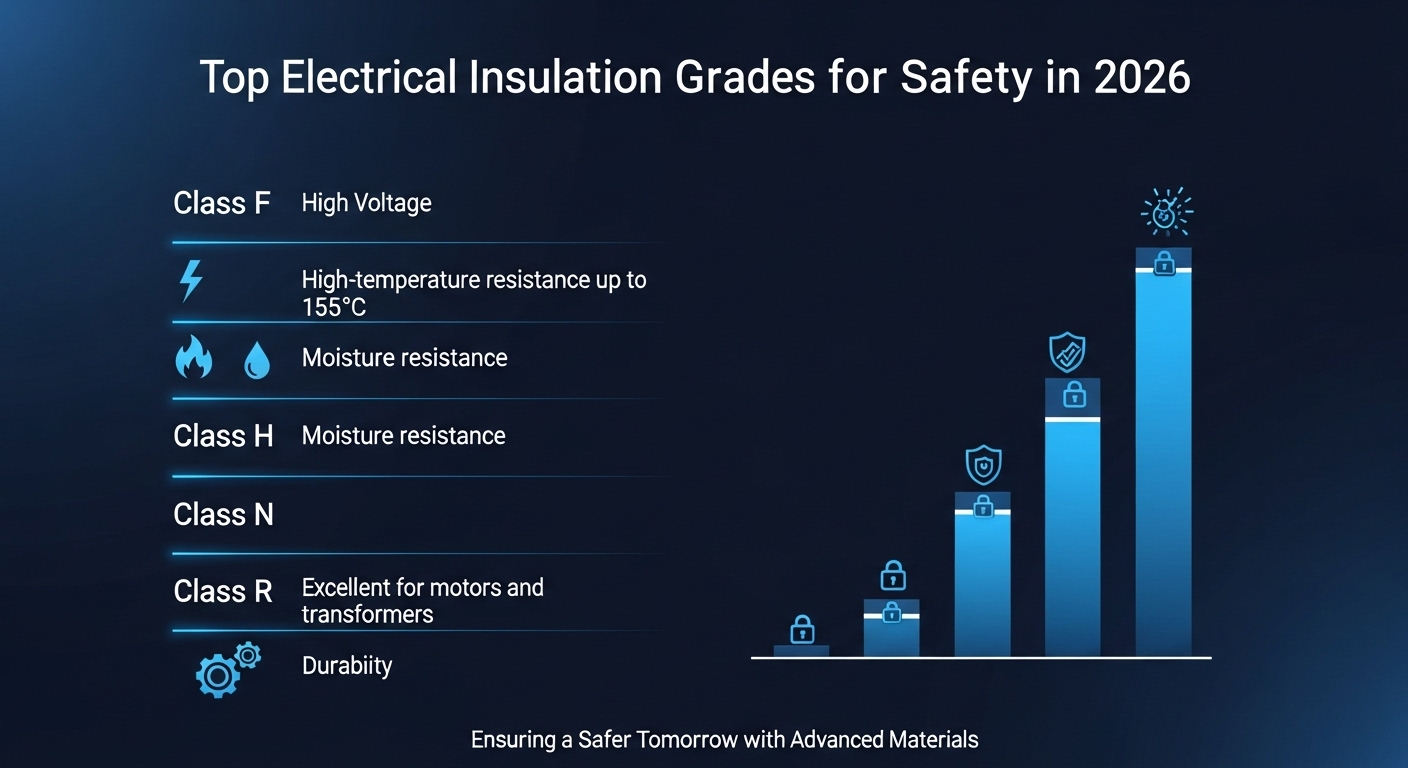

Top Electrical Insulation Grades for 2026

H Class (180°C) – High Heat Resistance

-

Temperature tolerance: Up to 180°C

-

Applications: Motors, transformers, and industrial equipment

-

Benefits: Excellent for high-temperature environments, long-lasting durability

B Class (130°C) – Standard Industrial Use

-

Temperature tolerance: Up to 130°C

-

Applications: Household appliances, small motors, wiring

-

Benefits: Balanced cost and performance, widely used for moderate environments

F Class (155°C) – Enhanced Thermal Safety

-

Temperature tolerance: Up to 155°C

-

Applications: High-performance motors, electrical generators

-

Benefits: Better thermal endurance than B class, ideal for longer-lasting performance

E Class (120°C) – Economic Choice

-

Temperature tolerance: Up to 120°C

-

Applications: General-purpose insulation

-

Benefits: Cost-effective, suitable for moderate heat loads

C Class (180°C+) – Advanced Safety Applications

-

Temperature tolerance: 180°C or higher

-

Applications: Aerospace, automotive, and critical industrial systems

-

Benefits: High reliability, extreme thermal resistance

Factors to Consider When Choosing Electrical Insulation

Choosing the right insulation grade is essential for both safety and performance. Consider the following factors:

-

Operating Temperature – Match insulation to your equipment’s typical temperature range.

-

Environmental Conditions – Moisture, chemicals, or outdoor exposure can degrade insulation.

-

Electrical Load – Higher voltage applications require stronger dielectric strength.

-

Cost vs. Longevity – Higher-grade insulation may cost more but lasts longer and reduces maintenance.

-

Regulatory Compliance – Always check standards like IEC, UL, or ANSI for safe applications.

Advantages of High-Grade Electrical Insulation

Using the right insulation grade provides multiple benefits:

-

Enhanced Safety: Reduces risk of electric shocks and fire hazards.

-

Improved Efficiency: Prevents energy losses due to heat or leakage.

-

Longer Equipment Life: Reduces wear and tear caused by electrical stress.

-

Compliance: Meets modern electrical safety standards.

Common Materials Used in Electrical Insulation

Understanding the materials helps in choosing the right grade:

-

Polyimide Films: High thermal and chemical resistance.

-

Epoxy Resins: Excellent mechanical strength and thermal stability.

-

Fiberglass: Durable and cost-effective for medium to high-temperature applications.

-

PVC & Rubber: Common for household wiring with moderate temperature tolerance.

Best Practices for Maintaining Electrical Insulation

To maximize safety and lifespan:

-

Inspect insulation regularly for cracks or discoloration.

-

Avoid overloading electrical systems.

-

Keep wiring away from moisture and chemicals.

-

Replace old or damaged insulation immediately.

Conclusion

Selecting the right electrical insulation grade is vital for safety, efficiency, and long-term performance. From E class to H class, understanding your environment and equipment needs ensures you make the best choice. By applying these guidelines, you protect both your devices and your loved ones from electrical hazards.

FAQ

Q1: What is the difference between B and F insulation grades?

A1: B grade handles up to 130°C, while F grade tolerates up to 155°C, offering better thermal endurance.

Q2: Can I use H-class insulation in household wiring?

A2: Technically yes, but it’s often unnecessary and more expensive than needed for home applications.

Q3: How often should electrical insulation be inspected?

A3: For high-risk or industrial setups, inspect annually; for household wiring, every 2–3 years.

Q4: Are all insulation materials suitable for outdoor use?

A4: No, some materials degrade under UV, moisture, or chemical exposure. Always choose weather-resistant types.

Q5: Does insulation grade affect electricity bills?

A5: Indirectly, yes. Better insulation reduces energy losses, improving efficiency and potentially lowering costs.