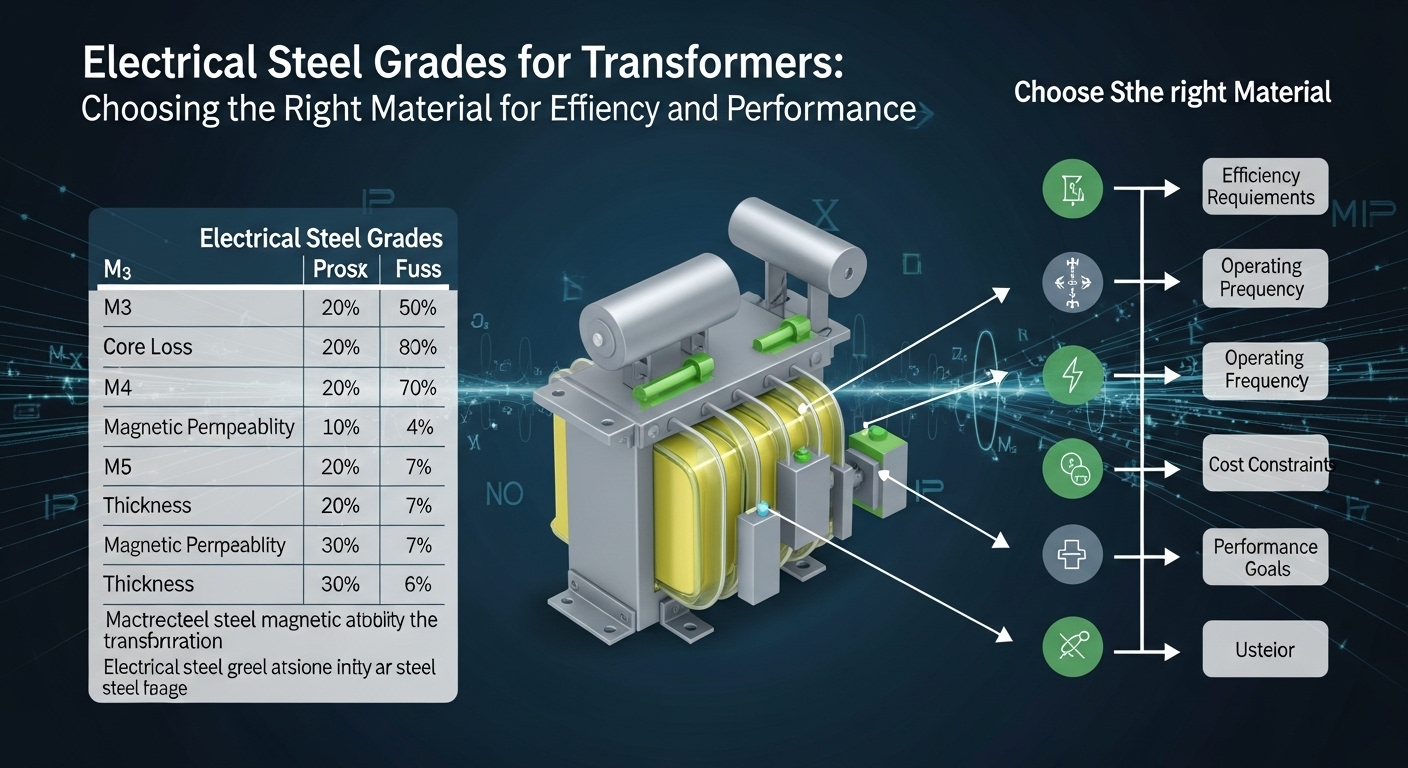

Electrical Steel Grades for Transformers: Choosing the Right Material for Efficiency and Performance

Transformers are the backbone of our electrical infrastructure, and the material used in their cores plays a critical role in performance. Electrical steel, a specially formulated steel designed to reduce energy loss, comes in various grades. Choosing the right grade can improve efficiency, reduce costs, and enhance transformer lifespan. In this article, we’ll explore different electrical steel grades for transformers, their features, and tips for selecting the ideal one for your project.

What Is Electrical Steel?

Electrical steel, also known as silicon steel, is a type of steel specifically designed to carry magnetic flux with minimal energy loss. It’s widely used in transformers, motors, and generators.

Key Features:

-

High magnetic permeability

-

Low hysteresis loss

-

Excellent insulation between sheets

-

Durable and resistant to mechanical stress

Types of Electrical Steel Grades

Electrical steel comes in several grades, each optimized for different applications. Here’s a breakdown:

1. Grain-Oriented Electrical Steel (GOES)

-

Best for: Transformers

-

Key Benefit: Oriented grains minimize energy loss along the rolling direction

-

Features:

-

High magnetic permeability

-

Low core loss

-

Available in 0.23mm to 0.35mm thickness

-

-

Applications: Power and distribution transformers

2. Non-Grain-Oriented Electrical Steel (NGOES)

-

Best for: Motors and generators

-

Key Benefit: Magnetic properties are uniform in all directions

-

Features:

-

Moderate magnetic permeability

-

Higher core loss than GOES

-

-

Applications: Electric motors, generators, alternators

3. High Silicon Electrical Steel

-

Best for: High-efficiency transformers and precision instruments

-

Key Benefit: Reduced eddy current losses

-

Features:

-

3–6% silicon content

-

Excellent electrical resistivity

-

-

Applications: Specialized transformers, electronic devices

How to Choose the Right Electrical Steel for Transformers

Selecting the right steel grade depends on multiple factors:

Consider the Following:

-

Transformer Type – Distribution transformers vs. power transformers may require different grades.

-

Core Loss Requirements – Lower core loss improves efficiency and reduces energy waste.

-

Thickness – Thinner sheets reduce eddy current losses but may cost more.

-

Cost vs. Performance – Balance budget constraints with energy efficiency goals.

-

Availability – Ensure the grade is available in your region for timely production.

Benefits of Using High-Quality Electrical Steel in Transformers

Investing in the right grade has several advantages:

-

Reduces energy losses and improves efficiency

-

Extends transformer lifespan

-

Reduces heating and cooling costs

-

Improves reliability in industrial and commercial applications

Tips for Maintaining Transformer Performance

Even the best electrical steel requires proper handling:

-

Avoid bending sheets beyond recommended limits

-

Use proper insulation between laminations

-

Perform routine checks for corrosion and damage

-

Store sheets in dry, controlled environments

Common Misconceptions

-

All electrical steel is the same – False. GOES and NGOES have different properties.

-

Thicker steel is always better – Not necessarily; it can increase eddy current losses.

-

High silicon content makes steel brittle – Modern alloys balance strength and conductivity.

Conclusion

Choosing the right electrical steel grade for transformers can dramatically improve efficiency, reduce losses, and extend operational life. Whether you select grain-oriented or high-silicon steel, understanding your transformer’s needs is key. Investing in quality materials now saves energy and costs in the long run.

Action Step: Evaluate your transformer requirements and consult with material suppliers to choose the best electrical steel grade. Share your experiences or questions in the comments below!

FAQ

1. What is the difference between GOES and NGOES?

GOES has grains aligned to reduce energy loss along one direction, ideal for transformers. NGOES has uniform properties for motors and generators.

2. Why is electrical steel used in transformers?

It minimizes core losses, improves efficiency, and allows for reliable magnetic flux conduction.

3. Can high-silicon steel improve transformer efficiency?

Yes, higher silicon content reduces eddy current losses, enhancing energy efficiency.

4. How do I maintain electrical steel in a transformer?

Store sheets properly, avoid over-bending, ensure proper insulation, and check for corrosion regularly.

5. Is thinner electrical steel better for transformers?

Thinner sheets reduce eddy current losses but may cost more and require careful handling.